High pressure

Applications

- Technical gases and hydrogen

- Automation and testing systems

- Oil & Gas

Description

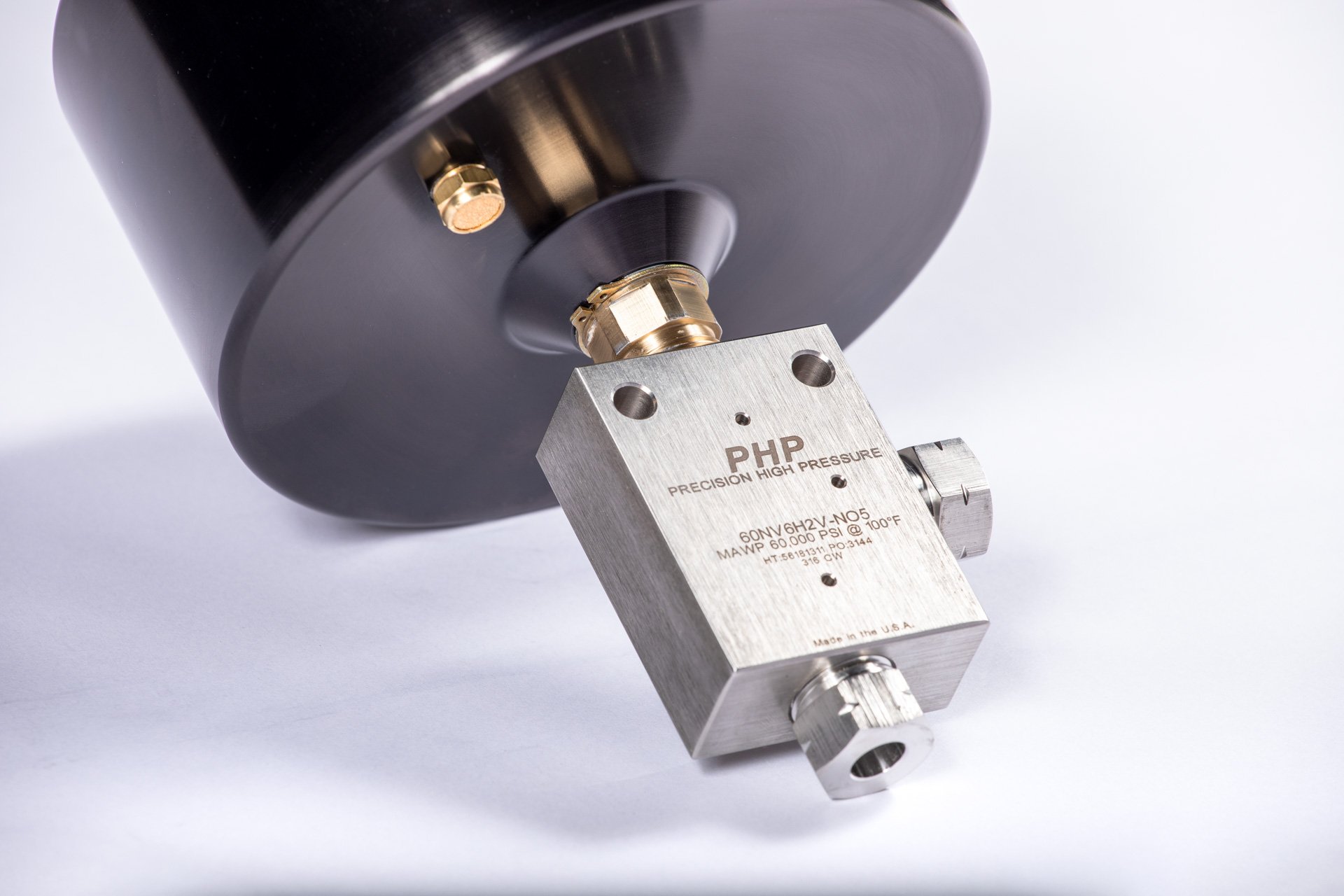

Manual needle valves

Needle valves offer maximum safety and reliability in handling flow, even in harsh operating conditions. These valves can be used bidirectionally and effectively isolate both liquids and gases. The heart of the valve is the specially shaped seat and the two-piece non-rotating stem. The longevity and reliability of these valves are ensured because the stem cannot lock against the seat. The pressure-containing parts are made of high-quality corrosion-resistant stainless steel. Reliability is documented through traceability, as each valve body includes references to trace its origin in case of issues. Medium-pressure (MP) and high-pressure (HP) valves come complete with collars and glands.

Actuated needle valves

High-pressure circuits can be automated using pneumatic actuated needle valves. The valve bodies and sealing system are identical to those of manual needle valves and offer the same advantages.

Actuated needle valves are available in the following versions: NC (normally closed), NO (normally open), and DA (double-acting).

All the brands we distribute use different materials for the needles compared to standard valves for valves designed for use with hydrogen.

In particular, PHP uses SUH660 material for its needles. SUH660 is a type of material composed of 25% Ni. A high Ni content helps to mitigate hydrogen embrittlement.

The remaining part of the needle valves is made of AISI 316, except for the actuator, which is made of aluminum.

There is also a pneumatic actuated version available. The actuators are made of aluminum and comply with ATEX directive.

Ball valves come in two types of connections: NPT and MP/HP coned and threaded. Additionally, this type of valve is available with electric or pneumatic actuators.

The available materials include:

- Body/Side Adapter/Trunnion: Cold-316 cold worked stainless steel.

- Packing: O-ring with PEEK backup ring.

- Seals: Viton

- Bearings: PEEK

The ball valves are made with end connections of 1/4, 3/8, 9/16, or 3/4 MP. The stem design and ball construction using trunnion technology ensure perfect alignment and sealing of gaskets.

These types of valves use high-durability sealing gaskets that have been tested up to 100.000 on/off cycles without leaks. The dynamic stem sealing is ensured by a double O-ring seal with special reinforcement rings.

PHP can assemble the valve with very tight tolerances so that the seals can seat under pressure.

Series and gaskets for low temperatures down to -40°C, and bearings made of PEEK.

Valves can be provided with NORSOK M-710 certification.

Needle Valve Features

- Maximum working pressure: from 10.000 psi to 101.000 psi (690-7000 bar)

- Standard valve body entirely made of AISI316, other materials available (Monel, Hastelloy, Inconel)

- Compatible with all liquids and gases

- Available connections: NPT, MP & HP from 1/8" to 1”

- Corrosion resistant

- Full traceability

- 15-5 PH stem for standard applications

- Special material stem for hydrogen applications

- Handle in AISI316/aluminum

- For MP and HP models with weep holes for easier leakage point verification

Ball Valve Features

- MAWP up to 20.000 psi (1380 bar)

- Temperature: from -28°C to 200°C

- Port sizes: 3/16, 1/4", 3/8" or 1/2"

- Types: 2-Way, 3-Way Switching, 3-Way Diverting

- Bidirectional trunnion

Advantages of Needle Valves

- Easy to use and incorporate

- Possibility of replacing seals (stem and seat)

- Operator safety

- Compact, lightweight, robust and weather proof

- Available with pneumatic actuators

- Available in versions for low and high temperatures

- Needle valves for hydrogen with special stem material

Alternative to:

- Haskel

- Maximator

- BuTech

- Autoclave

Are you interested in our products?

Register to Fluid-Hub.net, the digital portal for our products, and explore the online range.

Access Fluid-Hub.net, get an additional 2% discount, and many other benefits.

Choose the needle valve or ball valve you need and go directly to Fluid-Hub.net

| Brand | Average stock | Discover online availability |

|---|---|---|

| Nova Swiss | 🚚 Available from the supplier | ⌛ Soon online |

| Nova Swiss (Hydrogen use) | 🚚 Available from the supplier | ⌛ Soon online |

| PHP | ✅ Usually available | ⌛ Soon online |

| PHP (Hydrogen use) | ✅ Usually available | ⌛ Soon online |

| Brand | Average stock | Discover online availability |

|---|---|---|

| PHP | ✅ Usually available | ⌛ Soon online |

| Nova Swiss | 🚚 Available from the supplier | ⌛ Soon online |

| PHP (Hydrogen use) | ✅ Usually available | ⌛ Soon online |

| Nova Swiss (Hydrogen use) | 🚚 Available from the supplier | ⌛ Soon online |

| Brand | Average stock | Discover online availability |

|---|---|---|

| HIP | 🚚 Available from the supplier | ⌛ Soon online |

| Brand | Average stock | Discover online availability |

|---|---|---|

| PHP | 🚚 Available from the supplier | ⌛ Soon online |

| PHP (Hydrogen use) | 🚚 Available from the supplier | ⌛ Soon online |

Download

- Nova Swiss component for critical applications catalogue Download Nova Swiss component for critical applications catalogue

- Nova Swiss H2 needle valve catalogue Download Nova Swiss H2 needle valve catalogue

- PHP component catalogue Download PHP component catalogue

- PHP H2 component catalogue Download PHP H2 component catalogue

- HIP needle valve catalogue Download HIP needle valve catalogue

Why Your Fluid Mate?

Specialized technical support

We are at your support from the verification to the implementation of tailor-made diagrams and solutions

Automated warehouse

To monitor the order flow with precision, accuracy and speed

Wide range of products

We offer you multiple alternatives to quickly meet your request

Testing

We test the quality and parameters of the product you have chosen