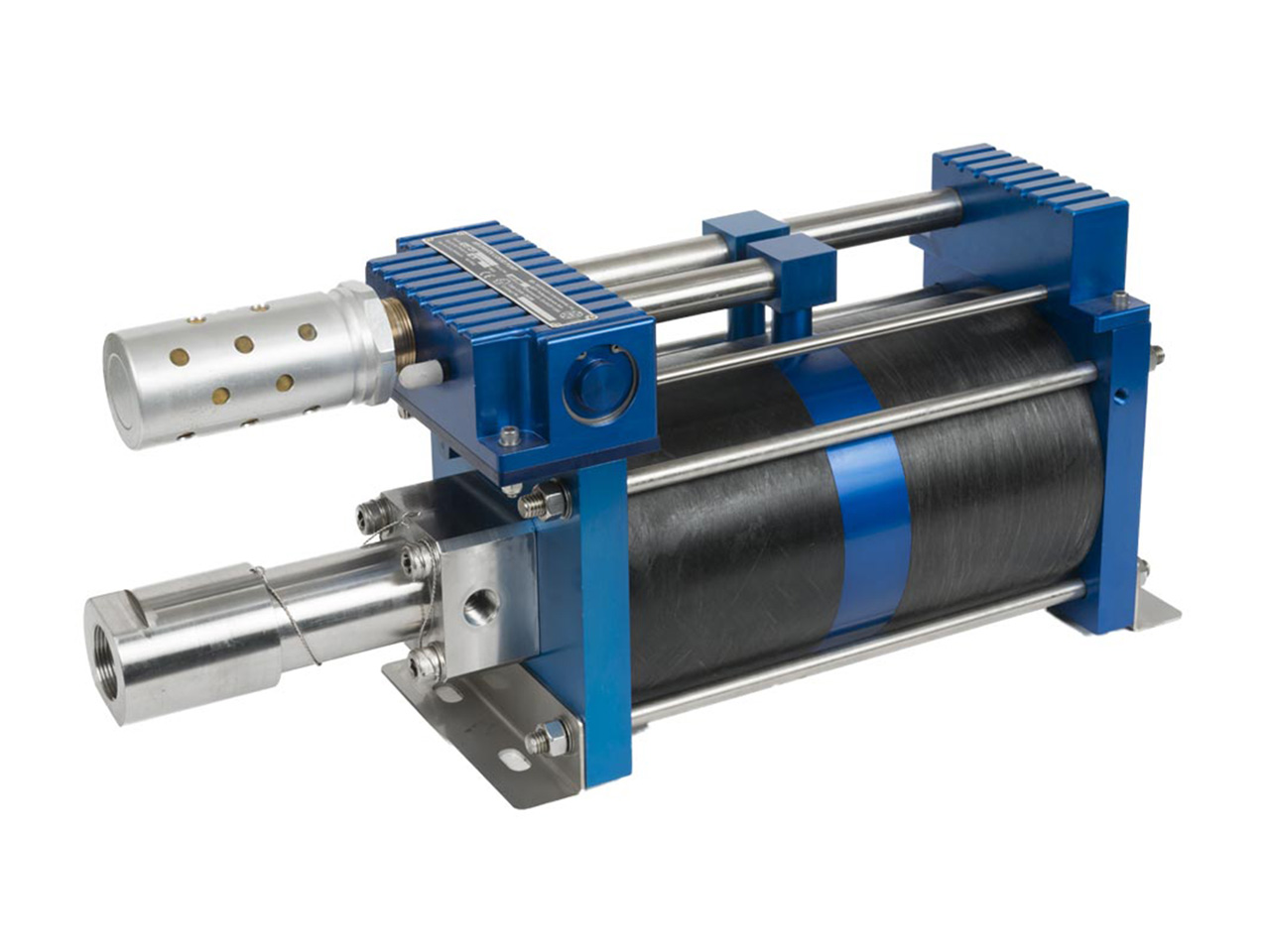

Air driven liquid pumpsIdeal for hydrostatic testing with water or oil

High pressure

Applicazioni

- Hydrostatic testing at high pressure of tubing, ducts, valves, cylinders, tanks

- Leak testing of components

- High pressure flushing unit

- Control panels/wellhead emergency shutdown

- Control/action of valve actuators

- Discover all applications ›

Description

Air driven liquid pumps convert compressed air into hydraulic pressure (up to 80.000 psi). No electrical connection or lubrication is required.

Hydraulic outlet pressure is equal to the drive air pressure multiplied by pump pressure ratio. Once the high pressure air-driven pump reaches the pre-set pressure it will automatically stall and maintain the pressure. In case of a pressure drop downstream, pump will automatically start and run.

High performance air-driven pumps, to provide an highly safe, reliable and long lasting hydraulic power source for applications up to 68.000 psi (4.688 bar).

These pumps are built to run at their maximum rated pressure and feature a robust motor and seal design that delivers a long lifetime. Moreover, they do not require a lubricated air source and incorporate several features to facilitate easy installation and service.

These pumps reach a “bubble tight” pressure stall that can be used for high pressure applications such as: valve actuation, hydraulic power units, bolt tensioning, jacking, lifting, power pressing, pressure testing and proof testing components, work holding and clamping, power pressing, proof testing components, hydraulic cylinder actuation, chromatography, lubrication and spraying, liquefied gas transfer.

Combining HiP’s high pressure expertise with Graco’s extensive pump engineering background, T-Series pumps address many of the shortcomings tipically found.

T-Series is available with Graco Datatrak electronic monitoring system equipped with:

- Stroke counter

- Cycle rate display

- Runway protection

Features

- Maximum working pressure: 80.000 psi (5500 bar)

- Compatible with all hydraulic fluids

- Stainless steel body and check valves in contact with liquid

- Drive air lubrication is not required

- Operate with compressed drive air (gas) from 116 psi (0.8 bar) to 145 psi (10 bar)

- Possible to drive with other inert gases

- Feed from mains or from a tank

Benefits

- Wide range of special modifications available

- Compact, lightweight, robust and weather proof

- Easy to incorporate and operate

- Ideal for START/STOP applications under load

Applications

- Hydrostatic testing at high pressure of tubing, ducts, valves, cylinders, tanks

- Leak testing of components

- High pressure flushing unit

- Control panels/wellhead emergency shutdown

- Control/action of valve actuators

- Power unit for tensioning – torque tools

- Packers inflation

- Press overload circuit

- Blocking cylinder actuation

- Burst test benches

Alternative to:

- Haskel

- Maximator

Are you interested in our products?

Register to Fluid-Hub.net, the digital portal for our products.

Buy directly online and get an extra 2% discount and many other benefits.

Choose the air driven liquid pump you need and go directly to Fluid-Hub.net

| Series | Average stock | Discover online availability |

|---|---|---|

| 3L-SS | ✅ Usually available | ⌛ Soon online |

| 5L-DD | 🚚 Orderable from the supplier | ⌛ Soon online |

| 5L-DS | 🚚 Orderable from the supplier | ⌛ Soon online |

| 5L-SD | 🚚 Orderable from the supplier | ⌛ Soon online |

| 5L-SS | ✅ Usually available | ⌛ Soon online |

| 5L-TS | 🚚 Orderable from the supplier | ⌛ Soon online |

| 7L-DD | 🚚 Orderable from the supplier | ⌛ Soon online |

| 7L-DS | 🚚 Orderable from the supplier | ⌛ Soon online |

| Series | Average stock | Discover online availability |

|---|---|---|

| SM-3 | 🚚 Orderable from the supplier | ⌛ Soon online |

| P4 | ✅ Usually available | ⌛ Soon online |

| S-216 | ✅ Usually available | ⌛ Soon online |

| S-525 | 🚚 Orderable from the supplier | ⌛ Soon online |

| Series | Average stock | Discover online availability |

|---|---|---|

| T6058 | 🚚 Orderable from the supplier | ⌛ Soon online |

| T6025 | ✅ Usually available | ⌛ Soon online |

| T6016 | 🚚 Orderable from the supplier | ⌛ Soon online |

| T6012 | 🚚 Orderable from the supplier | ⌛ Soon online |

| T6010 | 🚚 Orderable from the supplier | ⌛ Soon online |

| T6006 | ✅ Usually available | ⌛ Soon online |

| T6005 | 🚚 Orderable from the supplier | ⌛ Soon online |

| T6003 | 🚚 Orderable from the supplier | ⌛ Soon online |

| Series | Average stock | Discover online availability |

|---|---|---|

| T7568 | ✅ Usually available | ⌛ Soon online |

| T7557 | ✅ Usualli available | ⌛ Soon online |

| T7539 | 🚚 Orderable from the supplier | ⌛ Soon online |

| T7525 | 🚚 Orderable from the supplier | ⌛ Soon oline |

| T7519 | 🚚 Orderable from the supplier | ⌛ Soon online |

| T7516 | 🚚 Orderable from the supplier | ⌛ Soon online |

| T7510 | 🚚 Orderable from the supplier | ⌛ Soon online |

| T7507 | 🚚 Orderable from the supplier | ⌛ Soon online |

| T7505 | 🚚 Orderable from the supplier | ⌛ Soon online |

Download

- HII air driven liquid pumps catalogue Download HII air driven liquid pumps catalogue

- Sprague air driven liquid pumps catalogue Download Sprague air driven liquid pumps catalogue

- HIP T6000 and T7500 series air driven liquid pumps catalogue Download HIP T6000 and T7500 series air driven liquid pumps catalogue

Why Your Fluid Mate?

Specialized technical support

We are at your support from the verification to the implementation of tailor-made diagrams and solutions

Automated warehouse

To monitor the order flow with precision, accuracy and speed

Wide range of products

We offer you multiple alternatives to quickly meet your request

Testing

We test the quality and parameters of the product you have chosen